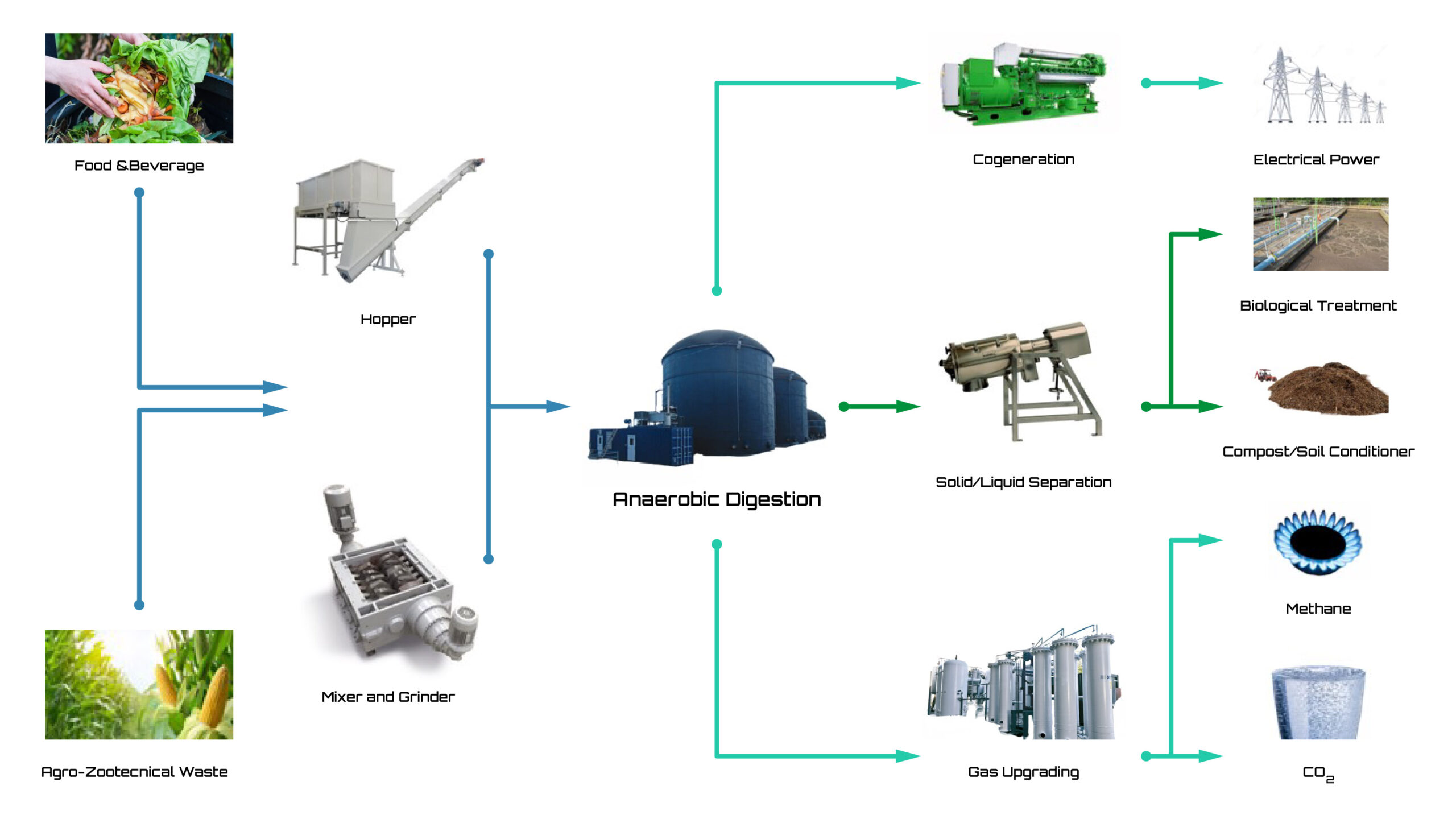

How Does It Work?

Anaerobic digestion is a biological process that involves the breakdown of organic matter in the absence of oxygen. It is commonly used to treat and manage various types of organic waste, such as agricultural residues, food waste, and sewage sludge, while also generating renewable energy in the form of biogas. The anaerobic digestion process typically takes place in a sealed tank called digester or anaerobic reactor.

Main steps of the process:

Feedstock

Organic waste materials are collected and prepared for digestion. The process may include shredding and grinding to increase the surface area of the feedstock and thus promote the further microbial digestion. In specific situations, further treatments such as thermal hydrolyzation can be used to enhance the biogas yield of the organic matter.

Loading

The feedstock, which can be an only one or a mixture of different organic materials, is daily put into the digester to maintain a constant biogas yield. The retention time – the average permanence time of the material into the digester – changes according to the substrate composition, but usually ranges between 25 and 35 days.

The Anaerobic Digestion.

Let’s have a “bio-chemical” look:

” Step by step”

The digester is sealed to create an oxygen-free environment, which is crucial as it promotes the growth of anaerobic microorganisms that carry out the digestion process. The microbial activity can be divided into four stages: hydrolysis, acidogenesis, acetogenesis and methanogenesis

HYDROLYSIS

In the hydrolytic step, complex organic compounds are broken down into simpler compounds where large molecules like proteins, carbohydrates, and fats are converted into smaller compounds such as sugars, amino acids, and fatty acids.

ACIDOGENESIS

The products of hydrolysis are further broken down by acidogenic bacteria that convert the simpler compounds into volatile fatty acids (VFAs) like acetic acid, propionic acid, and butyric acid.

ACETOGENESIS

In the acetogenesis stage, acetogenic bacteria convert VFAs into acetic acid, hydrogen, and carbon dioxide.

METHANOGENESIS

In the last phase of the process, acetic acid, hydrogen and carbon dioxide are further converted into methane (CH4) and carbon dioxide (CO2) by methanogenic microbes.

Biogas and Bio-Methane

“And That’s Not All Folks”

Usually, methane content in the biogas ranges between 55-65%, and CO2 ranges between 45-35%. it is possible to find other gasses in traces, such as water vapour and hydrogen sulphide (H2S)

that residue need to be removed thanks to a preliminary purification process. The purified biogas obtained from that process, can be used for electricity & heat generation.

The biogas can be further upgraded, using different methods in order to achieve an higher methane content gas (>95%). That product is called bio-methane and it can be used non only for the porpoused already listed, but also as biofuel .

The main biogas upgrading technologies:

Water Scrubbing

Water scrubbing, or water washing, is a simple and cost-effective biogas upgrading method. The raw biogas is passed through a water-filled column or tower, where impurities such as hydrogen sulphide (H2S), carbon dioxide (CO2), and other contaminants are absorbed by the water. The purified biogas, mainly consisting of methane (CH4), is then collected.

Pressure Swing Adsorption (PSA)

PSA is a widely employed biogas upgrading technology. It uses adsorbent materials, such as activated carbon or zeolites, to selectively adsorb CO2 and other impurities at high pressure. The impurities are subsequently released by reducing the pressure, leaving behind a purified methane-rich gas stream.

Membrane Separation

Membrane separation involves the use of semi-permeable membranes to separate CO2 and impurities from biogas. The membranes allow the smaller methane molecules to pass through, while larger CO2 and other contaminants are retained. This process can be conducted at ambient or elevated pressures.

Pressure Swing Membrane (PSM)

SM is a combination of pressure swing adsorption and membrane separation technologies. It utilizes selective membranes to separate CO2 and impurities from the biogas, and then applies pressure swing adsorption to remove the captured impurities from the membranes. This hybrid approach can achieve high-purity methane.

Amine Scrubbing

Amine scrubbing is a chemical absorption process that uses amines, such as monoethanolamine (MEA), to selectively capture CO2 from biogas. The raw biogas is passed through an amine solution, where CO2 reacts with the amine to form a stable compound. The remaining biogas, enriched with methane, is separated from the CO2-rich amine solution. The CO2 can be released from the amine through a desorption process, regenerating the amine for reuse.

Cryogenic Separation

Cryogenic separation involves cooling the biogas to very low temperatures, typically below -256°F, causing the CO2 and other impurities to condense and separate from the methane. The purified methane gas can then be collected, while the separated CO2 is typically vented or captured for further uses.

These are just a few examples of biogas upgrading technologies. Each method has its own advantages and considerations, such as energy requirements, capital costs, scalability, and specific gas quality targets. The choice of technology depends on factors such as the composition of the raw biogas, desired purity levels, project scale, and economic viability.

The Digestate Treatment:

The residual material left after digestion, known as digestate, can be used as a nutrient-rich fertilizer for agricultural purposes or undergoes additional processing to reduce its volume or to enhance the recovery of the nutrients. Given the chemical composition of this stream, a common treatment consist in transforming ammonia in other components by using denitrification-nitrification tanks. that process is followed by an ultra-filtration procedure, to separate sludge from purified water. Further treatment could be carried out on purified water to allow re-use (i.e. Reverse Osmosis) and obtain a nutrient-rich stream (i.e. Evaporation).

Why choose anaerobic digestion

because it plays a significant role in the circular economy and sustainable waste management practices.

Renewable energy production

Nutrient recycling

Waste management